Mastering Structural Steel Welding: Techniques, Tools, and Best Practices

Understanding Structural Steel Welding

Structural steel welding is a critical aspect of modern construction and fabrication processes, forming the backbone of countless structures ranging from bridges to buildings. As industries evolve and demand for stronger, more efficient materials rises, understanding the intricacies of this process becomes paramount for engineers, fabricators, and safety inspectors. Structural steel welding techniques not only ensure structural integrity but also contribute to the longevity and safety of constructed projects.

The Importance of Structural Steel Welding

Welding is the process of joining two or more materials, commonly metals, through melting and fusion. In the context of structural steel, welding is essential due to several reasons:

- Strength and Durability: Proper welding can create stronger joints than the material itself, offering superior load-bearing capabilities.

- Design Flexibility: Welded structures allow more intricate designs which can reduce material waste while maximizing space.

- Cost-Effectiveness: Efficient welding practices can reduce construction time and labor costs, leading to overall project savings.

- Safety Standards: When executed correctly, welding contributes to the overall safety of a structure, meeting or exceeding industry regulations.

Key Terminology in Structural Steel Welding

Familiarity with specific terminology is essential when working in structural steel welding. Key terms include:

- Weld Joint: The area where two or more pieces of metal come together to form a weld.

- Weld Bead: The metal deposited by the welding process to create a bond.

- Welding Electrode: A metal rod that provides filler material during the welding process.

- Heat Affected Zone (HAZ): The area of the metal that has not melted but whose microstructure is altered due to the heat of welding.

- Welding Procedure Specification (WPS): A document that provides direction for producing a weld.

Types of Structural Steel Welding Processes

There are various welding processes used in structural steel welding, each suitable for specific applications and materials:

- Shielded Metal Arc Welding (SMAW): Commonly known as stick welding, it uses a consumable electrode coated with flux to lay the weld.

- Gas Metal Arc Welding (GMAW): Also known as MIG welding, this process feeds a continuous wire electrode through a welding gun.

- Gas Tungsten Arc Welding (GTAW): Known as TIG welding, it uses a non-consumable tungsten electrode and is ideal for thinner materials.

- Flux-Cored Arc Welding (FCAW): Similar to MIG welding but uses a tubular wire filled with flux, which allows for outdoor use.

- Submerged Arc Welding (SAW): Uses a continuously fed filler wire and is characterized by a blanket of granular flux that protects the weld pool.

Essential Tools for Structural Steel Welding

To achieve successful welds, specific tools and equipment are necessary. Here’s a detailed overview of the essential equipment that should be in every welding toolkit.

Welding Equipment Overview

The backbone of any welding operation lies in the equipment used. Each type of welding comes with its own set of tools:

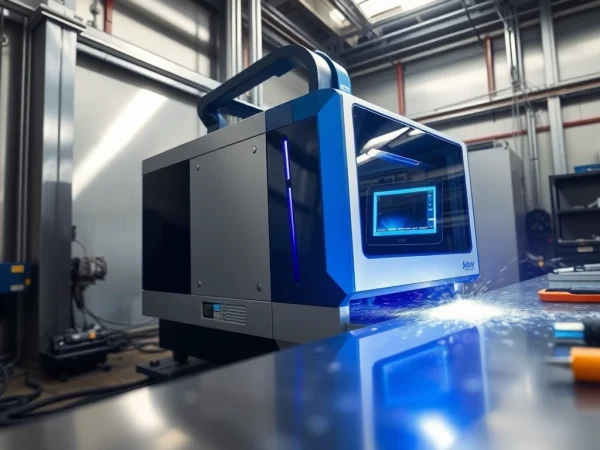

- Welding Machine: The most crucial piece of equipment, whether it’s a MIG, TIG, or stick welder.

- Welding Torches: Used for directing heat to the workpiece, with a variety for different welding types.

- Filler Materials: Depending on the welding type, this could be rods, wires, or other forms of metal.

- Welding Cables: Heavy-duty cables that carry power from the machine to the electrode or workpiece.

- Clamps and Fixtures: Essential for holding the pieces to be welded in place securely.

Protective Gear for Safe Welding

Safety is paramount in welding operations. Essential protective gear includes:

- Welding Helmet: Protects the eyes and face from sparks and UV radiation.

- Gloves: Heavy-duty gloves that withstand high heat and provide dexterity.

- Protective Clothing: Flame-resistant overalls or shirts to protect from heat and sparks.

- Steel-Toed Boots: Necessary for foot protection against heavy equipment and hot materials.

- Respirators: Critical when welding materials that may release harmful fumes.

Accessories to Enhance Structural Steel Welding

Beyond basic tools, several accessories can enhance the welding process and improve results:

- Welding Magnets: These help in holding metal pieces together at the correct angle.

- Grinders: Useful for preparing surfaces to be welded and finishing welds for a smooth surface.

- Weld Inspection Tools: Devices such as ultrasonic or magnetic particle testers help in evaluating weld quality.

- Welding Positioners: Equipment used to position workpieces in a manner that minimizes the need for awkward or unsafe postures for the welder.

- Welding Wire Feeders: In automated welding, these feeders help maintain a steady supply of filler material.

Techniques for Effective Structural Steel Welding

Understanding effective techniques is critical to achieving high-quality welds. Here are some tried-and-true methods to consider.

Preparation and Pre-Welding Steps

Proper preparation plays a vital role in the success of welding. Following these steps ensures the highest quality weld:

- Clean Surfaces: Remove rust, oil, and dirt to prevent contamination that could weaken the weld.

- Fit-Up: Ensure that the pieces to be welded fit snugly together without gaps.

- Check Alignment: Use fixtures, clamps, and tools to ensure components are properly aligned.

- Set Welding Parameters: Adjust the settings on welding equipment based on material type and thickness.

- Preheat Materials: Certain steels benefit from preheating to help reduce thermal stress during the welding process.

Common Welding Techniques Explained

Various techniques can be applied depending on the welding process and requirements:

- Weaving Patterns: This technique is used to create broader beads, providing better metal fusion.

- Stringer Beads: Involves a steady movement of the electrode for closer control, often used in thin materials.

- Backhand vs. Forehand Welding: The direction of travel can affect penetration and heat distribution.

- Multi-Pass Welding: For thicker materials, multiple passes are needed to achieve complete penetration.

- Controlled Cooling: Slowing the cooling rate after welding helps reduce the risk of cracking.

Troubleshooting Common Welding Issues

No welding process is without its challenges. Being able to identify and rectify issues is crucial:

- Porosity: Small holes in the weld can occur due to trapped gas. Ensure proper cleaning of the surfaces and a suitable shielding gas.

- Under-cutting: This defect occurs when the base metal is melted away. Adjust the travel speed and the angle of the welding torch.

- Insufficient Penetration: May result from incorrect settings or angles. Double-check welding speed and heat input.

- Cracking: Can be caused by stress or defects. Adequate preheating and proper filler material selection help alleviate this risk.

- Overheating: This results in warping and distortion. Monitor heat input carefully and utilize multi-pass techniques when suitable.

Quality Control in Structural Steel Welding

Maintaining high-quality welds requires stringent quality control measures. Here’s how this should be effectively conducted.

Standards and Compliance for Structural Steel Welding

Industry standards dictate the requirements for quality and safety in welding. Key organizations include:

- American Welding Society (AWS): Provides guidelines and certification for welding processes.

- American National Standards Institute (ANSI): Works to develop standards across various industries, including construction.

- ISO Standards: International standards that ensure quality and safety in welding practices globally.

- Bureau of Indian Standards (BIS): Ensures compliance with specific regulations for the Indian market.

- Local Building Codes: Compliance with local regulations is crucial for project approval and safety.

Visual and Non-Destructive Testing Methods

Testing ensures weld quality and compliance with safety standards. Common non-destructive testing methods include:

- Visual Inspection: The simplest form, identifying obvious defects.

- Ultrasonic Testing: Uses high-frequency sound waves to detect internal flaws.

- Radiographic Testing: X-rays or gamma rays are utilized to view the internal structure of welds.

- Liquid Penetrant Testing: This method detects surface cracks by applying a penetrant dye that seeps into flaws.

- Magnetic Particle Testing: Used for ferromagnetic materials, this method highlights surface and near-surface defects.

Ensuring Weld Integrity and Performance

Ensuring the integrity of welds is crucial for the overall performance of any structure. Best practices include:

- Regular Inspections: Scheduling routine inspections post-welding to catch any deterioration early.

- Documentation: Keeping detailed records of welding procedures, inspections, and maintenance contributes to accountability.

- Training and Certification: Regularly upskilling welders and inspectors to keep pace with evolving standards and techniques.

- Material Quality Control: Ensure that all materials meet specified standards before use in any project.

- Environment Considerations: Awareness of environmental factors that may affect welding quality, such as humidity and temperature.

Future Trends in Structural Steel Welding

The field of structural steel welding is continually evolving, driven by technological advancements, innovative materials, and sustainability practices.

Technological Advancements Shaping the Industry

Emerging technologies are poised to revolutionize the way structural steel welding is carried out:

- Automation: The use of robotic welding systems increases speed and consistency while reducing labor costs.

- 3D Printing: This innovative technology is beginning to influence metal fabrication, allowing for rapid prototyping and customized designs.

- Augmented Reality (AR): AR is being integrated into training programs to enhance learning through simulated welding scenarios.

- Smart Welding Equipment: IoT-enabled machines that offer real-time data analysis, enhancing precision and monitoring.

- Advanced Filler Materials: Innovations in filler materials that provide better mechanical properties and resistance to corrosion.

Innovations in Materials and Methods

The demand for lighter, stronger materials is driving innovation in welding methods:

- High-Strength Low-Alloy (HSLA) Steels: These materials provide enhanced strength while reducing weight.

- Composite Materials: The use of steel with materials such as carbon fiber is gaining traction due to their combined benefits.

- Self-Healing Materials: Although still in the experimental stages, these could significantly improve the longevity of welded structures.

- Welding of Dissimilar Materials: Techniques that allow for effective welding of different metals without compromising quality.

- Enhanced Thermal Management: Innovations in controlling heat affected zones to avoid common issues like warping and cracking.

Sustainability Practices in Structural Steel Welding

Increasing awareness of environmental impact is pushing for sustainable practices in structural steel welding:

- Recycling of Materials: Using scrap steel and other recyclables in new constructions minimizes waste and conserves resources.

- Energy-Efficient Processes: Developing welding techniques that reduce energy consumption during production increases sustainability.

- Carbon Neutral Welding: Research into materials and processes that offset carbon footprints is becoming a focal point.

- Green Certifications: Seeking certifications that indicate compliance with environmental regulations can enhance the marketability of welding operations.

- Innovation in Packaging and Transport: Changes in how materials are shipped and stored reduce overall environmental impact.